Sahel Ettehad MFG. CO., LTD

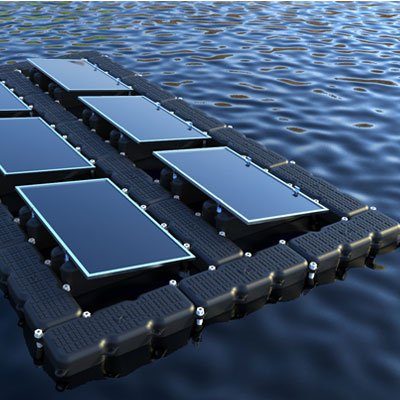

Sahel Ettehad Manufacturing Company with the SEMCO-Plast brand, manufactures all kinds of plastic barrels, blow-molding industrial parts, fuel tanks, hospital bed parts, building concrete construction molds, wind turbines and floating solar panel equipment