SEMCOPLAST CHEMICAL PRODUCTS

Sahel Ettehad Manufacturing Company (Semcochemical), based on demands and requirements of different industries is capable of formulating and manufacturing of chemical products. our company has experience in the manufacturing of Epoxy curing agents and methods for wastewater treatment etc.

COMPOSITE MATERIAL

Car Industries, Military Equipment, Aerospace

EPOXY HARDENER

High quality Epoxy products with variety of applications

ULTRASONIC CLEANING SOLUTION

Acidic, Neutral, Alcaline

WASTEWATER TREATMENT

Any plant with any contaminant type

EPOXY CURING AGENT

Using the knowledge of experienced experts and studying new products, Semcochemical Group has formulated and produced different epoxy resin hardeners (stone coat, composite, flooring, etc).

Sahel Ettehad Company is ready to accept cooperation projects and agreements.

EPOXY RESIN APPLICATION

Today, epoxy resin is used in various industries such as plastic, rubber, composite, glue, varnish, paint and textile industry. The main consumption of resins is in packaging, flooring, paper, printing, paint, leather, agriculture and oil industries.

COMPOSITE EPOXY

Epoxy composites are a type of polymer material that uses an epoxy resin to create a polymer matrix which is reinforced with fibers or other fillers.

EPOXY ART

High-gloss epoxy resin clear coat that makes pieces POP while protecting them.

PRIMER AND COATING

Floaring and coating applications

STONECOAT EPOXY

Strengthening, polishing, repairing cracks and microcracks behind and on the stone, increasing the useful life of stone materials

EPOXY RESIN AND HARDENER

Epoxy resin systems consist of two parts, an “A” and a “B” side. The B side, also known as the “hardener”, is the epoxy curing agent; the curing agent is responsible for reacting with the epoxy groups contained in the epoxy resin A side. Reaction of curing agents with epoxy resins results in hard, thermoset materials. The parameters effecting the product final:

Hardener type

Epoxy type

Filler content

Crosslinking Mechanism

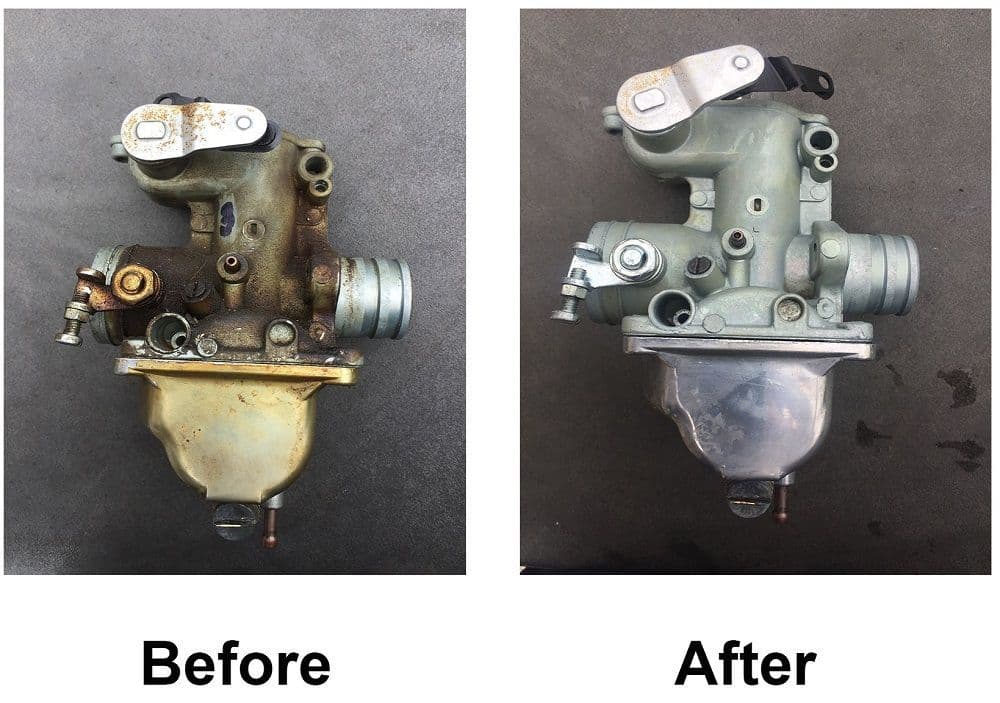

ULTRASONIC CLEANING SOLUTION

Aqueous ultrasonic cleaning solutions are water-based, degreasers. They can be used to clean most metals including stainless steel, carbon steel, brass, copper, magnesium, as well as most plastics, ceramics, and composite materials.

Sediment Separation

Lime and mineral deposits, rust

Organic Compound Removal

Removal of pollution from tires, metals, glass and plastic

Removal of any contaminant

Soot, hard grease, wax, metal particles and dust on mechanical parts

Washing Sensitive Parts

Jewelry, ceramics, glass, boards and electronics

Proper Staining

Eliminate the effects of oxidation

Removal of Sensitive Metal's Pollution

Rust Prevention in sensitive metals

WASTEWATER TREATMENT

The major aim of wastewater treatment is to remove as much of the suspended solids as possible before the remaining water, called effluent, is discharged back to the environment. As solid material decays, it uses up oxygen, which is needed by the plants and animals living in the water. Relying on the knowledge of experienced experts in this field, Sahel Ettehad Company (Semco-Chemical) declares its readiness to design and implement industrial wastewater treatment plants.

Removal of all Types of Industrial Pollutants

Heavy metals, mercaptans, colored pollutants

Design and implementation of Waste Stabilization Ponds

According to the type of pollutant and production capacity of industries

Extraction of Reaction Byproducts

Part return of the wastewater treatment costs

High Efficiency of Chemical Wastewater Treatment

Efficiency of 88% in 4 consecutive cycles

PROPERTIES OF EPOXY RESIN

Long Working Time

Long service life of manufactured parts

High Adhesion Capabilities

Adhesion to metals and vast variety of materials

High Mechanical Strength

Tensile, compressive and bending strength

Curing Capability at Different Temperatures

Room temperature and heat furnaces curing

Dimension Stability

Non -elasticity and non -elasticity deformation

NO Shrinkage

Non -deformation of the angles of the final piece

Fatigue Resistance

Exalted fatigue resistance

Chemical Resistance

Excellent chemical resistance (especially in alkaline environments)

Electricity Insulation

Excellent electricity insulation